Our Services

Infrastructure

-

Sheet Metal Fabrication

-

Laser Cutting

-

NC Press Brake

-

Tube Bending

-

Shearing Machine

-

Power Press

-

Powder Coating & Spray painting

-

Sheet/Plate Rolling Machine

-

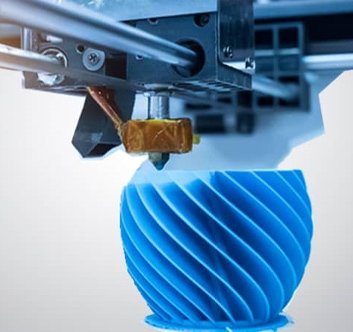

Design & 3D Printing

Sheet Metal Fabrication is creating three-dimensional metal objects from two-dimensional metal sheets. This process often includes fabricating components and pieces from sheet metals of various sorts. It’s a versatile method that can produce many different metal parts from materials, including aluminium, steel, stainless steel, copper, and brass.

Sujaya Industries uses the latest equipment and technology, enabling them to take your plans and produce the sheet metal fabrication product to your requirements you need in a timely manner and on a budget. We have vast knowledge and experience in forming and working with sheet metal fabrication. We approach our fabrication projects with focused attention on details and superior customer service.

Our Laser Cutting Services give our customers the advantages of extreme accuracy, material maximization, the elimination of hard tooling, and the ability to accommodate creative geometric design and thicker materials.

The precision, speed and versatility of our high wattage CNC laser cutting systems enable us to provide our customers with excellent, cost-efficient solutions, quick turnaround and superior quality results.

Technical Specifications:

CRCA/HR: 0.5-16mm

Stainless Steel: 0.5-8mm

Galvanised Iron: 0.5- 8mm

Aluminium: 1-3mm

Brass and copper: 1-2mm

A Press Brake is a piece of manufacturing equipment that is used to bend sheet metal. It is typically narrow and long so that large pieces of sheet metal can be bent by it. A press brake bends sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die. The metal may be bent several times by a press brake until the desired form has been achieved.

Technical Specifications:

- Make: Energy Mission

- Capacity: 160 Ton

- Length: 3m

- Two axis automatic control – bending degree(Y Axis) and back guage (X-Axis) program

- The back gauge repeated position accuracy within +_0.1mm

Hydraulic Semi Auto pipe bending machine

- Capacity pipe dia 12mm to 55mm

- Dia 50.8mm pipe radius 115mm

- Maximum Ovelty = 5%

TEE Make mechanical Shearing Machine with 25HP Motor which can cut plates upto 12mm thickness

Heavy duty “C” Frame geared power presses capacity of 30 Tons, 50 Tons and 100 Tons

Capacity | 30 Tons | 50 Tons | 100 Tons |

Adjustability of Stroke (in mm) | 5-60 | 10-80 | 10-120 |

Adjustability of Ram (in mm) | 25 | 25 | 30 |

Shut Height (Adjustability of Up stroke down) (in mm) | 255 | 325 | 390 |

Centre to Back (in mm) | 200 | 255 | 315 |

Opening in Bed (Dia) (in mm) | 190 | 240 | 350 |

Powder Coating offers a durable, long-lasting finish that is resistant to chipping, scratching, and corrosion, making it ideal for parts exposed to harsh environments. Spray painting, on the other hand, allows for a smooth, even application of paint, enhancing the visual appeal of fabricated items with a wide range of color and finish options. Together, these techniques ensure that fabricated products not only perform exceptionally well but also maintain their appearance over time, meeting the highest standards of quality and durability.

Technical Features: Bottom roll are fixed and driven by Gears and worm Reduction Gear Box. Top Roll rotates in fixed positions and can be adjusted up & down manually by adjustable screws.

Bending Process: Place the Plate between bottom and top rolls by adjusting top roll manually. Down the top roll and give pressure on the plate. Then start Main motor in clock wise direction till one end of the plate comes over first bottom roll reverse the motors and get second end on second bottom Continue above process until you get desired roll size.

Plate Rolling Machine Application & Usage: Boiler Tank, Air Conditioning Channels, Sheet Metal Cover Cone Making & Other Aluminum & Steel Fabrication, Marine & Ship Building, Pressure Vessels, and Wind Mills.

Technical Specifications:

Capacity in MM for Mild steel: 1250*6

Top Roll: 125

Bottom Roll: 105

Motor in H.P: 3

Computer-aided design (CAD) is the use of computers (or workstations) to aid in the creation, modification, analysis, or optimization of a design.

CAD is an important industrial art extensively used in many applications.

Our team includes designers and engineers who perform advanced modeling and detailed fabrication drawings suitable for the most complex, packaged equipment and modularized assemblies. With our enhanced CAD simulation tools, we can help our customers analyze their designs before we build prototypes.

From design to delivery, we have the knowledge and expertise to provide our customers with complete product solutions that are cost-effective and of the highest quality.

Powder coating and spray painting are essential processes in the fabrication industry, providing both protective and aesthetic benefits to metal components.